News

Position 1

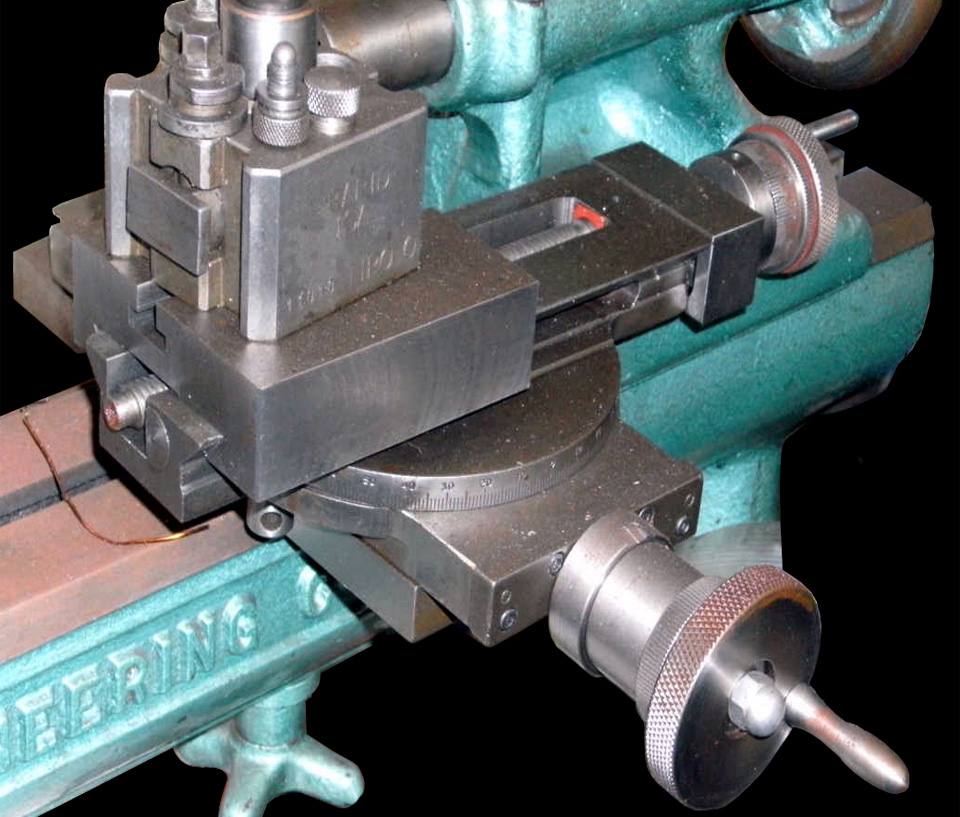

Tool maker – Bench Fitting

Number of vacancies -1

Qualified Toolmakers with 3-4 years experience in injection mold and die casting tool manufacturing. Interested candidates must

- Have good knowledge of injection mould and diecast tool(Zinc and Aluminium)

- Be able to work independently on all tool room machines and equipment.

- Be independently able to plan and manufacture complete mould from supplied mould design drawing.

- Be able to blue-match and assemble complicated moulds with complex shut off, (blank off/bedding ) angle lifts, floating core, multiple slides etc .

- Have experience in manufacturing hot runner mould with multiple drop manifold.

- Have experience in manufacturing moulds with hydraulic, air or cam operated core pullers.

Position 2

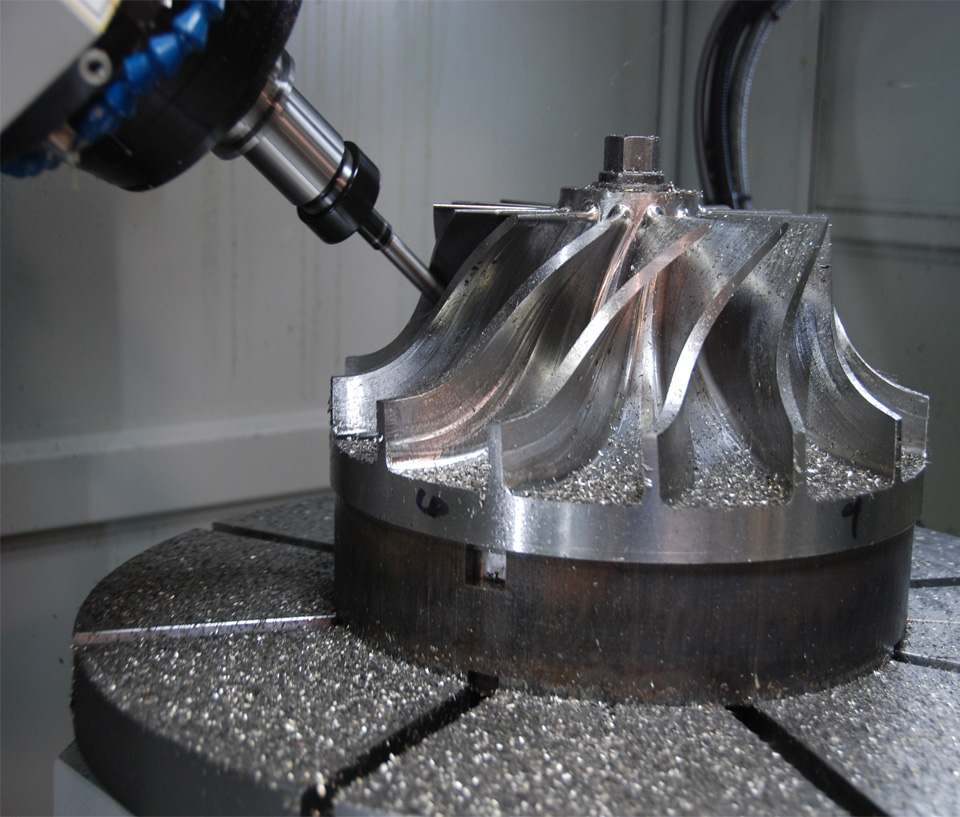

Tool makers: 3D CNC programmer/CNC Machinist

Number of vacancies -1

Qualified Toolmakers with 4-6 years experience in injection mold and die casting tool manufacturing. Interested candidates must

- Have 2-3 years experience in Precision Tool making.

- Have 2-3 years experience in 3d programming for CNC machining of injection mould and die casting tools.

- Be capable of generating tool path for CNC machining from mould design drawing and tool models.

- Be independently able to set up and machine jobs on CNC machining centres with automatic tool changer.

- Be able to CAD model injection moulds and die casting tools using CAD/CAM software.

- Have knowledge of injection mould and Diecasting tool design.

- Be able to decide on machining procedures and options like CNC machining, Grinding,EDM, wire cut etc..

- Be independently able to design ,cad model and CNC machine electrodes for eroding mould details.

Tradesmen with hands on experience in the respective areas are encouraged to apply. Qualified person must be able to work hands work involvement from raw material to product approval.

Interested person may send your detailed resume with a declaration of your ability to meet the task, to tooling@acon.com.au. Please emphasis on what you are capable of doing than what you have learned and where you have worked.

Position 3

Apprentice-Toolmaker

Number of vacancies -1

Prime Tooling Pty Ltd is a medium size Tool room Specialises in manufacturing Precision injection moulds. The manufacturing process involves use of Computerised Precision machines and equipment with highly skilled operators.

We are offering a Trade Apprenticeship in Tool-making.

You will be attending NSW TAFE as part of your apprenticeship and working in a workshop environment learning the trade from a team of experienced Toolmakers.

Interested person must be HSC completed with good record in Maths and Science.Some technical background in Engineering drawing and metal machining is preferred. Candidates must have initiative to complete a four year apprenticeship.

Please send your resume to work@primetooling.com.au or

Prime Tooling Pty Ltd

“Apprenticeship”

3/4 Garling Road,

Kings Park,

NSW – 2148.